YOU'RE LOOKING TO MAKE YOUR FACTORY SMARTER. BUT WHAT EXACTLY DOES THAT MEAN?

Smart manufacturing means to:

-

Operate more efficiently

-

Get products to market faster and more profitably

-

Reduce waste/rework of parts

-

Minimize product recalls

-

Increase manufacturing flexibility (e.g. enable multi-model production lines)

Want to know more about LMI sensors? Book your free demo now!

THE CHALLENGES IN AUTOMOTIVE INDUSTRY

In the automotive industry, automation poses a number of quality control issues. To enhance efficiency, minimise costs, and increase yield, these factory processes require a sophisticated 3D machine vision system.

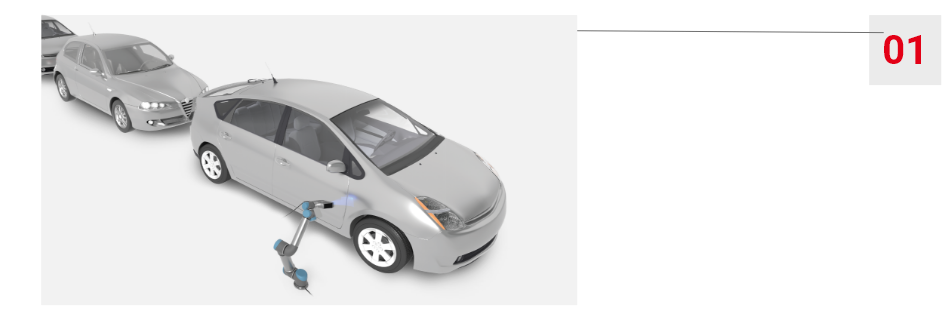

Flexible automation

This is the ability for a robot or system to be quickly and easily re-tasked on the fly. Flexible automation requires the solution to have the ability to sense, think, and act – and ultimately adapt to changes in manufacturing.

Better quality control

The goal of automotive sector, as in every other industry, is to obtain 100 percent quality control. Not first article inspection (FAI) or random inspection, but scanning and examining every single part and assembly on the line. Pass/Fail decision on vehicle components, assemblies, and final finish are made using data obtained during the scanning and inspection cycle.

Achieve your manufacturing goals with Industry 4.0 upgraded LMI Gocator sensor technology

Gocator 3D smart sensors provide a complete solution for 3D scanning, measurement, and control in automotive factory automation process.

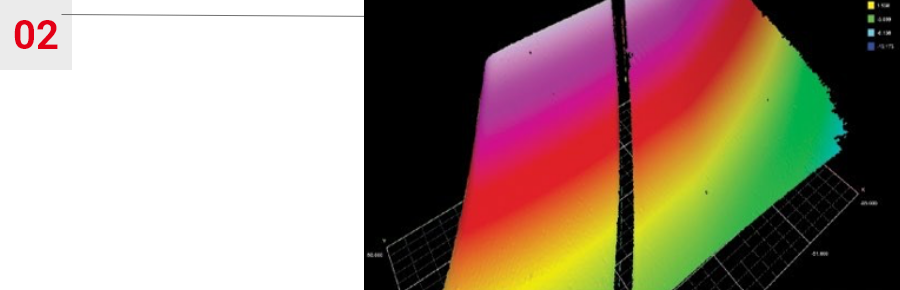

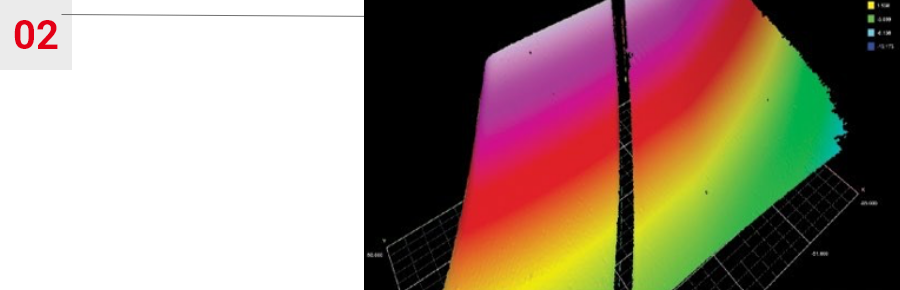

FROM PHYSICAL TO DIGITAL

The smart 3D solution is both easy and highly efficient. Gocator scan physical target to convert them into 3D digital files. This enables producers to take digital measurements, make control decisions, and obtain high quality results in real world.

Quality control decision making

Gocator makes critical pass/fail decisions and communicates this directly to factory networks and equipment –all within a single package, and all at production speed.

GOCATOR 3D SMART SENSORS

HIGH-SPEED 3D LASER POINT PROFILE SENSORS

-

High speed dimensional measurement (surface roughness, object thickness) up to 32khz

-

Pre calibrated ready to measure

-

scalable to synchronized multiple sensor network

-

small footprint- Fits into tight spaces

-

No software needed, directly setup and control via web browser

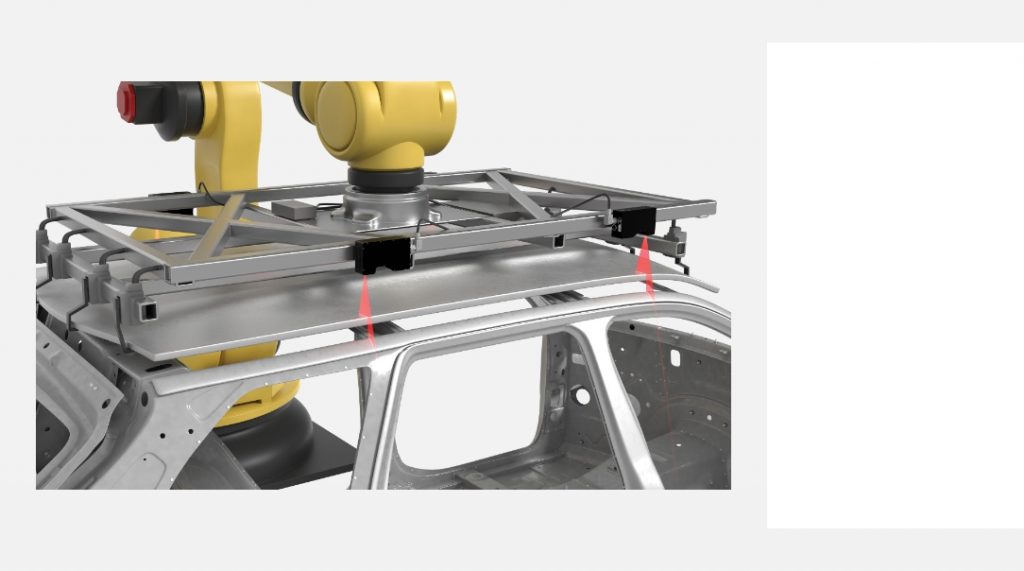

Gocator Line sensors (3D smart sensors)

-

Gocator laser line profile sensors are ideal for simple component and assembly inspection in robotic and fixed measurement applications.

-

Available in various models, with fields of view ranging from 10mm to 1.26m

-

Built in tools and network protocols, no programming.

-

Gocator line sensors can perform various functions including: roof insertion, glass insertion, and panel insertion.

-

Choose these sensors when you need to verify correct dimensions such as standoff, size, and position.

HIGH-RESOLUTION 3D SNAPSHOT SENSORS

-

Gocator 3D snapshot sensors use structured light to deliver advanced 3D inspection of automotive parts, assemblies, and final fit and finish.

-

Complete 3D point cloud in a single snapshot

-

Ideal for robotic inspection applications

-

Accurate 3D measurement with blue led pattern projection

-

These sensors are ideal for robotic vision guidance (RVG), flexible robotic inspection, fixed measurement and high tolerance inspection applications.

OUR CUSTOMERS

You’re looking to make your factory smarter. But what exactly does that mean?

Smart manufacturing means to:

1) Operate more efficiently

2) get products to market faster and more profitably

3) Reduce waste/rework of parts

4) Minimize product recalls

5) Increase manufacturing flexibility (e.g. enable multi-model production lines)

Want to know more about LMI sensors? Book your free demo now!

You’re looking to make your factory smarter. But what exactly does that mean?

Smart manufacturing means to:

1) Operate more efficiently

2) get products to market faster and more profitably

3) Reduce waste/rework of parts

4) Minimize product recalls

5) Increase manufacturing flexibility (e.g. enable multi-model production lines)

Want to know more about LMI sensors? Book your free demo now!

The challenges in automotive industry

In the automotive industry, automation poses a number of quality control issues. To enhance efficiency, minimise costs, and increase yield, these factory processes require a sophisticated 3D machine vision system.

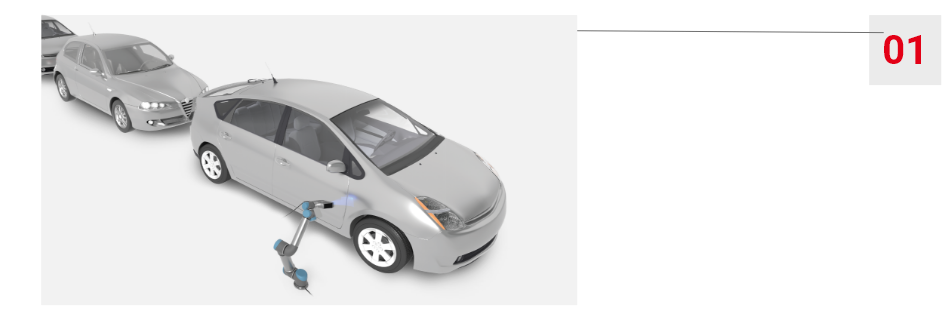

Flexible automation

This is the ability for a robot or system to be quickly and easily re-tasked on the fly. Flexible automation requires the solution to have the ability to sense, think, and act – and ultimately adapt to changes in manufacturing.

Better quality control

The goal of automotive sector, as in every other industry, is to obtain 100 percent quality control. Not first article inspection (FAI) or random inspection, but scanning and examining every single part and assembly on the line. Pass/Fail decision on vehicle components, assemblies, and final finish are made using data obtained during the scanning and inspection cycle.

Achieve your manufacturing goals with Industry 4.0 upgraded LMI Gocator sensor technology

Gocator 3D smart sensors provide a complete solution for 3D scanning, measurement, and control in automotive factory automation process.

FROM PHYSICAL TO DIGITAL

The smart 3D solution is both easy and highly efficient. Gocator scan physical target to convert them into 3D digital files. This enables producers to take digital measurements, make control decisions, and obtain high quality results in real world.

Quality control decision making

Gocator makes critical pass/fail decisions and communicates this directly to factory networks and equipment –all within a single package, and all at production speed.

GOCATOR 3D SMART SENSORS

HIGH-SPEED 3D LASER POINT PROFILE SENSORS

-

High speed dimensional measurement (surface roughness, object thickness) up to 32khz

-

Pre calibrated ready to measure

-

scalable to synchronized multiple sensor network

-

small footprint- Fits into tight spaces

-

No software needed, directly setup and control via web browser

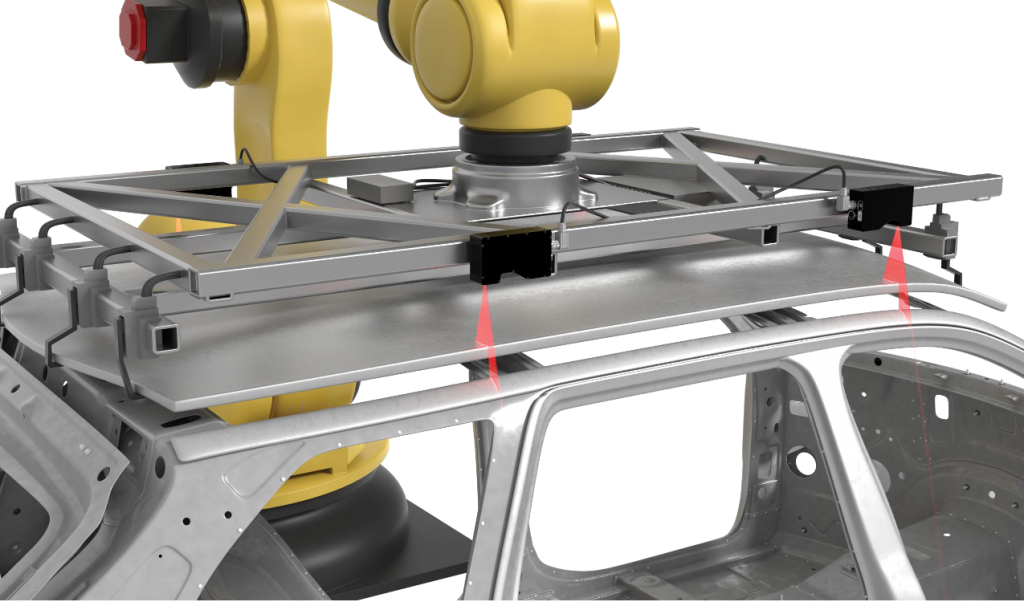

GOCATOR LINE SENSORS (3D SMART SENSORS)

-

Gocator laser line profile sensors are ideal for simple component and assembly inspection in robotic and fixed measurement applications.

-

Available in various models, with fields of view ranging from 10mm to 1.26m

-

Gocator line sensors can perform various functions including: roof insertion, glass insertion, and panel insertion.

-

Choose these sensors when you need to verify correct dimensions such as standoff, size, and position.

GOCATOR LINE SENSORS (3D SMART SENSORS)

-

Gocator laser line profile sensors are ideal for simple component and assembly inspection in robotic and fixed measurement applications.

-

Available in various models, with fields of view ranging from 10mm to 1.26m

-

Gocator line sensors can perform various functions including: roof insertion, glass insertion, and panel insertion.

-

Choose these sensors when you need to verify correct dimensions such as standoff, size, and position.

HIGH RESOLUTION 3D SNAPSHOT SENSORS

-

Gocator 3D snapshot sensors use structured light to deliver advanced 3D inspection of automotive parts, assemblies, and final fit and finish.

-

Complete 3D point cloud in a single snapshot

-

Ideal for robotic inspection applications

-

Accurate 3D measurement with blue led pattern projection

-

These sensors are ideal for robotic vision guidance (RVG), flexible robotic inspection, fixed measurement and high tolerance inspection applications.

HIGH RESOLUTION 3D SNAPSHOT SENSORS

-

Gocator 3D snapshot sensors use structured light to deliver advanced 3D inspection of automotive parts, assemblies, and final fit and finish.

-

Complete 3D point cloud in a single snapshot

-

Ideal for robotic inspection applications

-

Accurate 3D measurement with blue led pattern projection

-

These sensors are ideal for robotic vision guidance (RVG), flexible robotic inspection, fixed measurement and high tolerance inspection applications.

OUR CUSTOMERS