TAKE A LOOK AT

30000+ CUSTOMERS TRUST MICRO.VU INCLUDING:

Trusted by big and small brands

“No Problem solve all your problems with VMM accessories”

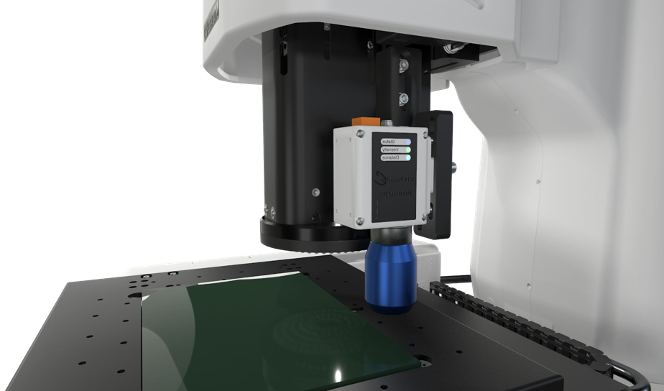

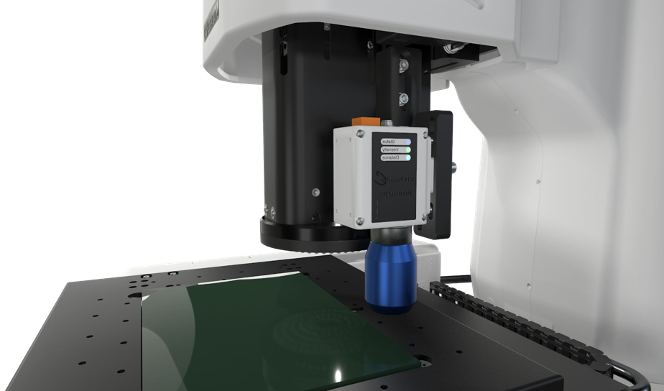

Micro-Vu vision measurement machine by default comes with the vision sensor is usually capable to inspect maximum amount of dimensions.

However some dimensions are such that they can be only measured by sensors with various capabilities such as probes, lasers and rotary.

Micro-Vu vision measurement machine has the capability to integrate with such sensors so as to provide a complete and quick solution to all your inspection priorities.

Instead of investing in a brand new machine just for inspecting specific dimensions, add our sensors to your machine at fraction of a cost.

“No Problem solve all your problems with VMM accessories”

Micro-Vu vision measurement machine by default comes with the vision sensor is usually capable to inspect maximum amount of dimensions.

However some dimensions are such that they can be only measured by sensors with various capabilities such as probes, lasers and rotary.

Micro-Vu vision measurement machine has the capability to integrate with such sensors so as to provide a complete and quick solution to all your inspection priorities.

Instead of investing in a brand new machine just for inspecting specific dimensions, add our sensors to your machine at fraction of a cost.

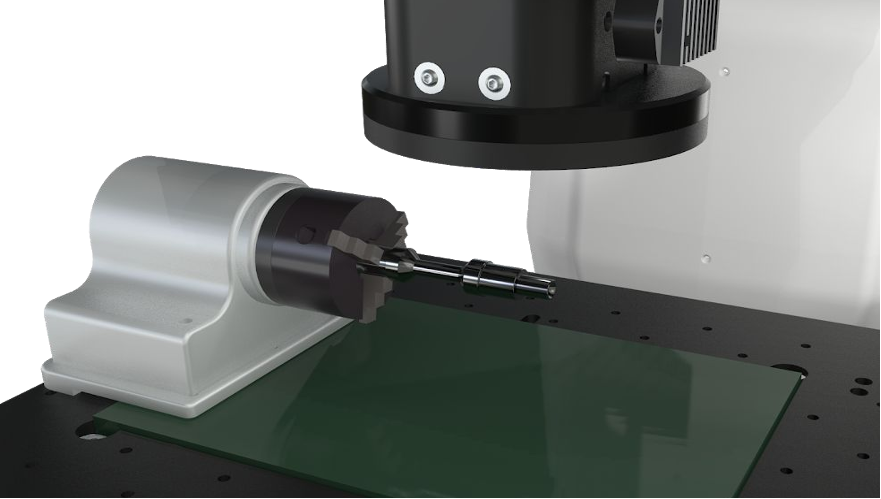

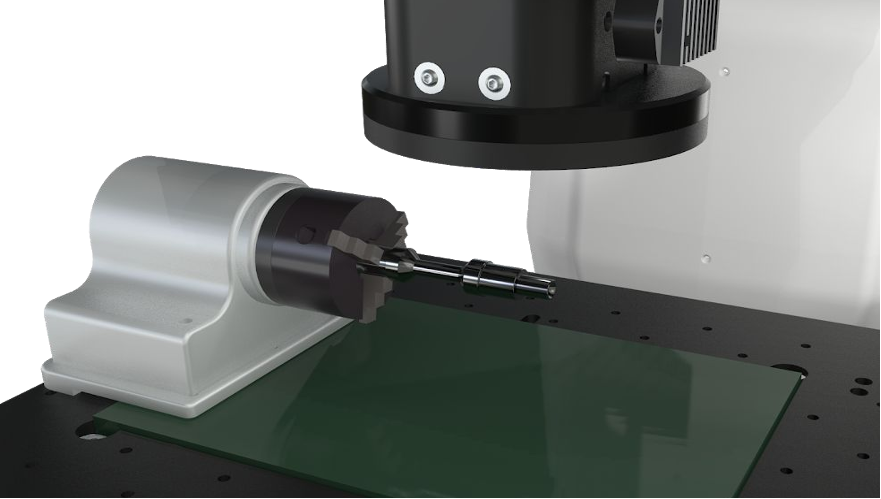

The RSD-60 rotary device can be mounted vertically or horizontally on the vertex and excel machine models. InSpec software integrates the rotary seamlessly and offers an intuitive on-screen interface. The rotary allows rotating parts to a position relative to a coordinate system or the current position. This device is commonly used for measurement of medical and dental parts, bits, cutters, valves, fittings, and multi sided parts.

The RSD-60 rotary device can be mounted vertically or horizontally on the vertex and excel machine models. InSpec software integrates the rotary seamlessly and offers an intuitive on-screen interface. The rotary allows rotating parts to a position relative to a coordinate system or the current position. This device is commonly used for measurement of medical and dental parts, bits, cutters, valves, fittings, and multi sided parts.

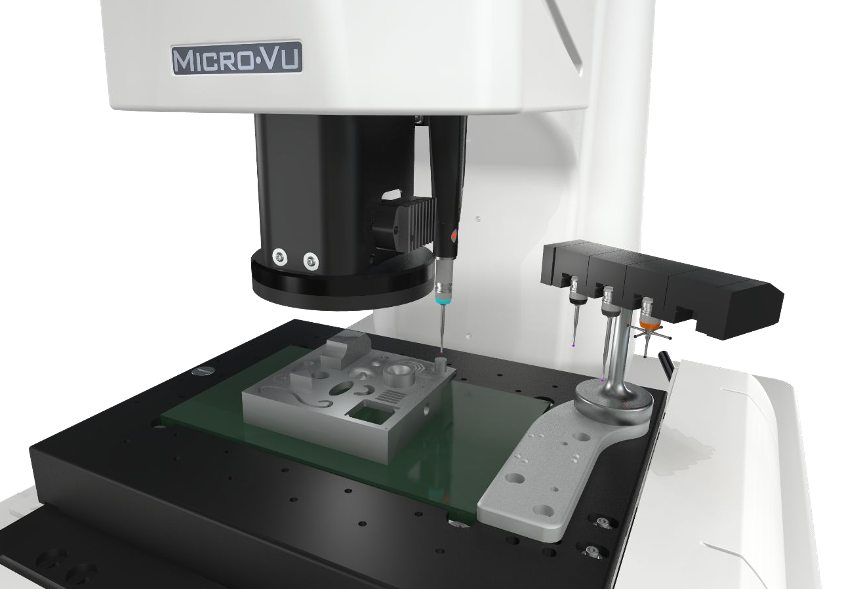

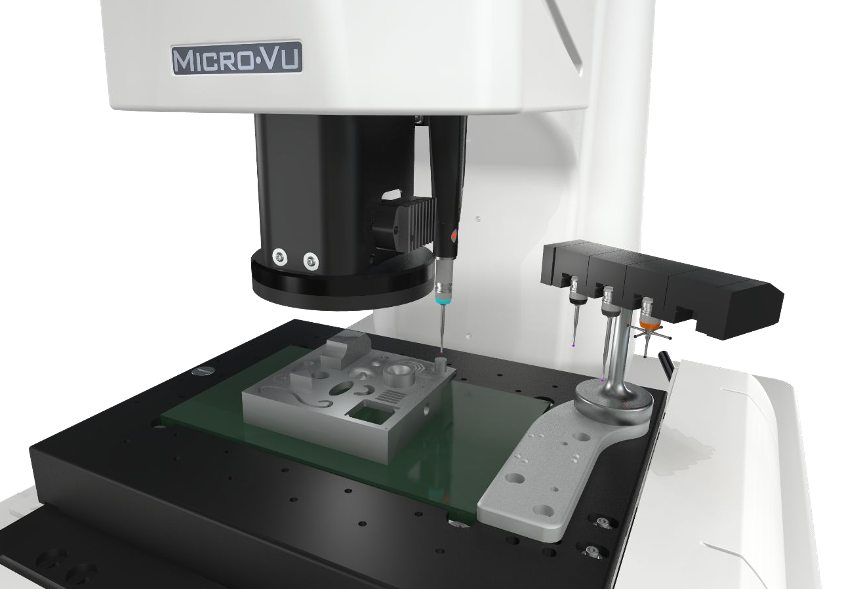

Touch probe will support your organization in inspecting various types of dimensions which are only accessible by a probe and not visible to the camera. It will also support your organization in inspecting components in one single orientation without shifting parts.

Touch probe will support your organization in inspecting various types of dimensions which are only accessible by a probe and not visible to the camera. It will also support your organization in inspecting components in one single orientation without shifting parts.

Micro-Vu Multi-sensor measuring systems are equipped and ready to incorporate laser triangulation sensors. Specular and diffuse mode configurations are available. The distance sensor collects data as it moves between two programmed XYZ locations, ideal for surface flatness and Z distance measurements.

Micro-Vu Multi-sensor measuring systems are equipped and ready to incorporate laser triangulation sensors. Specular and diffuse mode configurations are available. The distance sensor collects data as it moves between two programmed XYZ locations, ideal for surface flatness and Z distance measurements.

Trusted by big and small brands

Trusted by big and small brands